- 您现在的位置:买卖IC网 > Sheet目录1993 > DS1123LE-100+ (Maxim Integrated Products)IC DELAY LINE 256TAP 16-TSSOP

DS1123L

3.3V, 8-Bit, Programmable Timing Element

6

______________________________________________________________________

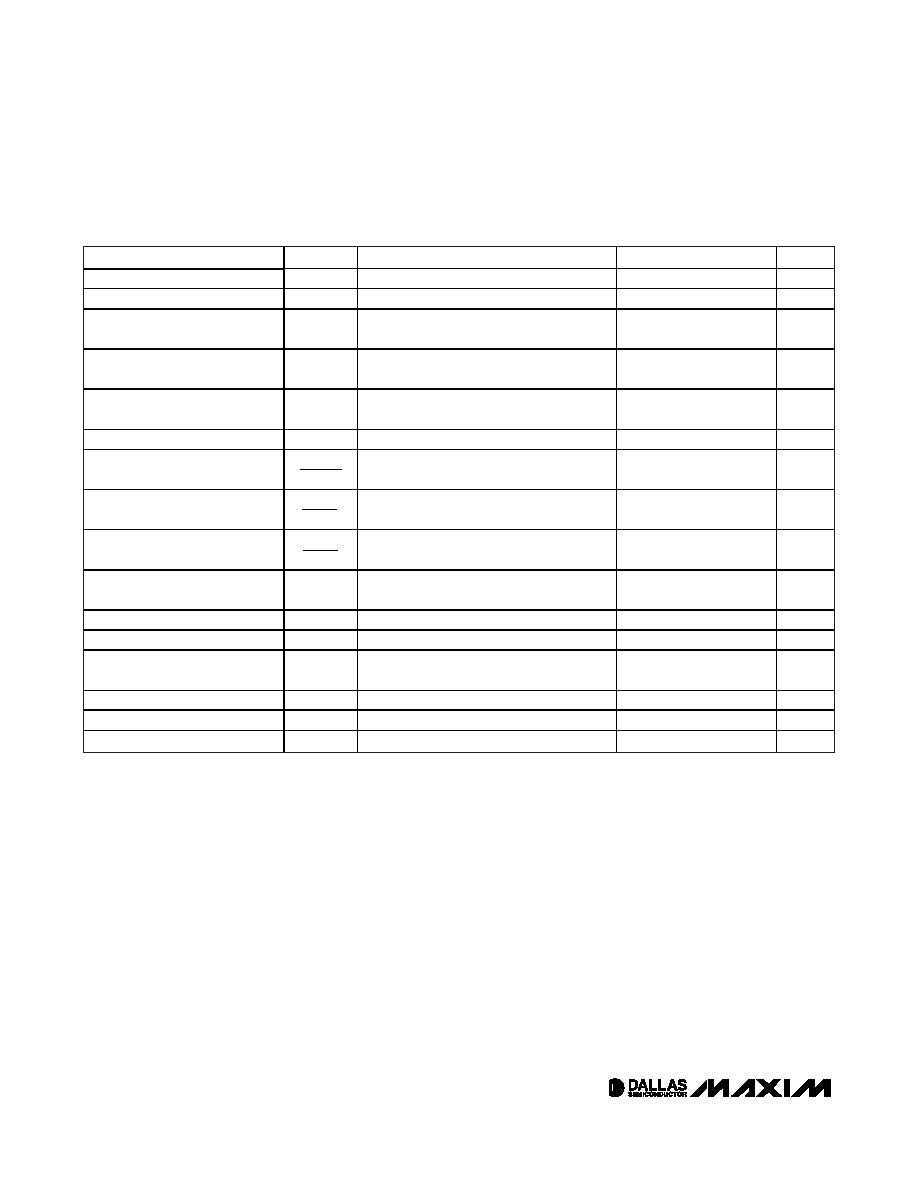

AC ELECTRICAL CHARACTERISTICS (DS1123L-100)

(VCC = +3.0V to 3.6V, TA = 0°C to +70°C.)

PARAMETER

SYMBOL

CONDITIONS

MIN

TYP

MAX

UNITS

Reference Delay

tREF

(Notes 3, 4)

18

22

ns

Delay Step Size

tSTEP

TA = +25°C

0

1

2.25

ns

Step-Zero Delay with Respect

to IN

tD0

(Notes 4, 5)

16.5

22

ns

Step-Zero Delay with Respect

to REF

tD0REF

(Notes 6, 7)

-2.5

-1.5

0

ns

Maximum Delay with Respect

to IN

tDMAX

(Notes 4, 8)

272

ns

Delay with Respect to REF

tDREF

Position FF (Notes 7, 9)

255

ns

Delay with Respect to REF

Tolerance

VCC = 3.3V, TA = +25°C

(Notes 7, 9)

-0.75

+0.75

%

Voltage Delay Variation

(Notes 7, 9)

-0.5

+0.5

%

Temperature Delay Variation

VCC = 3.3V (Notes 7, 9)

-2.5

+2.5

%

Integral Nonlinearity (Deviation

from Straight Line)

terr

(Note 10)

-4

0

+4

ns

OUT Delta Delay

tINV0

(Note 11)

0

1

2.5

ns

IN High to PWM High

tPWM0

(Notes 4, 12)

16.5

22

ns

Minimum PWM Output Pulse

Width

tPWM

(Note 13)

5

ns

Minimum Input Pulse Width

tWI

(Note 14)

40

ns

Minimum Input Period

(Note 15)

80

ns

Input Rise and Fall Times

tr, tf

(Note 16)

0

1

s

Note 1:

All voltages are referenced to ground.

Note 2:

If IN is high during power-up, the output remains low until IN is toggled low and back high again.

Note 3:

The reference delay is closely matched to the step-zero delay to allow relative timings down to zero or less.

Note 4:

Measured from rising edge of the input to the rising edge of the output (tDR).

Note 5:

Delay from input to output with a programmed delay value of zero.

Note 6:

This is the relative delay between REF and OUT. The device is designed such that when programmed to zero delay the

OUT output always appears before the REF output. This parameter is numerically equal to tD0 - tREF (see Figure 8).

Note 7:

From rising edge to rising edge.

Note 8:

This is the actual measured delay from IN to OUT. This parameter exhibits greater temperature variation than the relative

delay parameter.

Note 9:

This is the actual measured delay with respect to the REF output. This parameter more closely reflects the programmed

delay value than the absolute delay parameter (see Figure 8). Typical delay shift due to aging is within ±0.85%. Aging

stressing includes level 1 moisture reflow preconditioning (24hr +125°C bake, 168hr +85°C/85%RH moisture soak, and

three solder reflow passes +260°C +0°C/-5°C peak) followed by 1000hr (max) VCC biased +125°C OP/L, 1000hr unbi-

ased +150°C bake, and 1000 temperature cycles at -55°C to +125°C.

Δt

t

DREF

Δt

t

DV

DREF

Δt

t

DT

DREF

发布紧急采购,3分钟左右您将得到回复。

相关PDF资料

DS1124U-25+T

IC DELAY LINE 256TAP 10-USOP

DS1135LU-300/T&R

IC DELAY LINE 300NS 8-USOP

DS1135Z-12/T&R

IC DELAY LINE 12NS 8-SOIC

DS1181LE+

IC CLOCK MOD SS 8-TSSOP

DS1243Y-120

IC NVSRAM 64KBIT 120NS 28DIP

DS1244W-120IND

IC NVSRAM 256KBIT 120NS 28DIP

DS1248Y-70IND

IC NVSRAM 1MBIT 70NS 32DIP

DS1251WP-120+C02

IC NVSRAM 34PWRCP

相关代理商/技术参数

DS1123LE-200

功能描述:延迟线/计时元素 Programmable 3.3V 8 Bit Timing Element RoHS:否 制造商:Micrel 功能:Active Programmable Delay Line 传播延迟时间:1000 ps 工作温度范围: 封装 / 箱体:QFN-24 封装:Tube

DS1123LE-200+

功能描述:延迟线/计时元素 Programmable 3.3V 8 Bit Timing Element RoHS:否 制造商:Micrel 功能:Active Programmable Delay Line 传播延迟时间:1000 ps 工作温度范围: 封装 / 箱体:QFN-24 封装:Tube

DS1123LE-25

功能描述:延迟线/计时元素 Programmable 3.3V 8 Bit Timing Element RoHS:否 制造商:Micrel 功能:Active Programmable Delay Line 传播延迟时间:1000 ps 工作温度范围: 封装 / 箱体:QFN-24 封装:Tube

DS1123LE-25+

功能描述:延迟线/计时元素 Programmable 3.3V 8 Bit Timing Element RoHS:否 制造商:Micrel 功能:Active Programmable Delay Line 传播延迟时间:1000 ps 工作温度范围: 封装 / 箱体:QFN-24 封装:Tube

DS1123LE-50

功能描述:延迟线/计时元素 Programmable 3.3V 8 Bit Timing Element RoHS:否 制造商:Micrel 功能:Active Programmable Delay Line 传播延迟时间:1000 ps 工作温度范围: 封装 / 箱体:QFN-24 封装:Tube

DS1123LE-50+

功能描述:延迟线/计时元素 Programmable 3.3V 8 Bit Timing Element RoHS:否 制造商:Micrel 功能:Active Programmable Delay Line 传播延迟时间:1000 ps 工作温度范围: 封装 / 箱体:QFN-24 封装:Tube

DS1123LS-200

功能描述:延迟线/计时元素

RoHS:否 制造商:Micrel 功能:Active Programmable Delay Line 传播延迟时间:1000 ps 工作温度范围: 封装 / 箱体:QFN-24 封装:Tube

DS1123LS-25

功能描述:延迟线/计时元素

RoHS:否 制造商:Micrel 功能:Active Programmable Delay Line 传播延迟时间:1000 ps 工作温度范围: 封装 / 箱体:QFN-24 封装:Tube